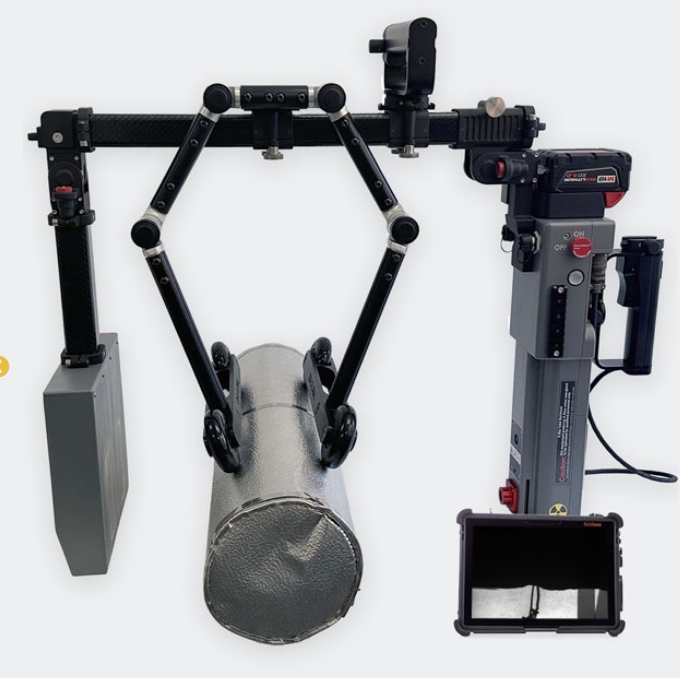

OpenVision™ HD Real-Time Radiography X‑Ray System for CUI Inspection

Description

Reduce CUI inspection and maintenance costs with rapid visual screening and highly accurate results.

OpenVision HD is a handheld real-time radiography x-ray system that helps radiographers quickly screen insulated piping systems for indications of corrosion, such as pitting, scaling, external wall loss, and wet insulation. It can also be used for heat trace and weld location mapping.

We designed OpenVision HD with aircraft-grade aluminum housings and stainless-steel reinforced joints for long term use in demanding environments. It’s ideal for screening piping systems with common insulation and cladding.

OVHD is lighter, more versatile and more durable than its predecessor, increasing inspection productivity in every way. The lighter design makes OVHD deal for NDT companies using rope-access technicians to conduct CUI studies. Improved image quality and software enhancements make OVHD the premier inspection tool in CUI inspection. Features such as the newly enhanced intuitive operator interface make OVHD more accurate and efficient.

A patent-pending combination of a c-arm, mounted 70 kV x-ray source, and digital CMOS detector panel allows

you to observe external defects as small as 0.010-inch (250 micron) on insulated piping.

Features:

- Intuitive Operator Interface.

- 8 Hour Battery Life.

- No Warm-up Time.

- No Hanging Cables.

- Wireless Video Monitor.

- Improved HD Image Quality.

- Hi-Resolution Video and Image Reporting.

- Built-In Controller.

- 24% Lighter.

- Enhanced Safety Capabilities.

OpenVision HD can be used on various insulation and cladding combinations, including mineral wool and calcium silicate with galvanized steel, stainless steel, and aluminum cladding up to 91 cm in total diameter.