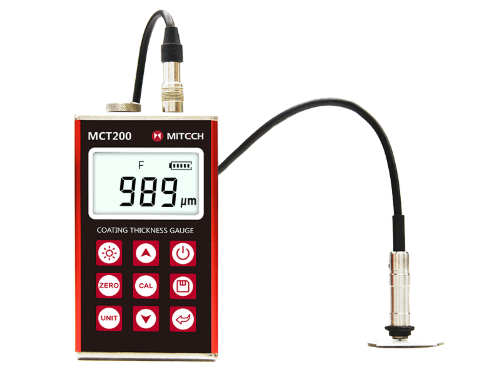

Mitech MCT200 Coating Thickness Gauge

Description

The Mitech MCT200 Coating Thickness Gauge is a portable coating thickness gauge that can swiftly and accurately test the thickness of coatings on various metallic substrates, without damaging the coated surface. It can be used in a wide variety of fields including manufacturing, metal-processing and asset inspection.

Specifications:

- Measuring principle: Magnetic induction & Eddy current.

- Measuring range: (0~1250) μm, depending on probes. Maximum 10 mm for the probe F10.

- Low range resolution: 0.1 μm.

- Accuracy: ±(3%Thickness+1) μm, depending upon probes and conditions.

- Display:4 digits LCD with EL backlight.

- Memory: for up to 20 files (up to 50 values for each file) of stored values.

- Unit system: Metric (μm) or Imperial (mil).

- Power source: Two “AA” size, 1.5 Volt alkaline batteries. 200 hours typical operating time.

- Dimensions:125 mm×67 mm×31 mm.

- Weight:340 grams.

Features:

- With different external probes, the gauge can be applied to measuring thickness of non-magnetic coating on magnetic metal substrate, as well as non-conductive coating on non-magnetic metal substrate.

- Five types of probes (F400, F1, F10, N1, CN02) are available for different applications. F10 probe measures up to 10 mm.

- Two measuring modes: single or continuous.

- Two calibration methods can be applied to the gauge – system error of the probe can be corrected with the basic probe calibration method.

- Measured values and user information are shown on a large, easy-to-read LCD screen. A display back light ensures easy reading of screen data in poorly-lit conditions.

- Measuring status indicator.

- The gauge’s user-friendly measuring system permits automatic storage of up to 1000 readings in one memory matrix for later statistical evaluation.

- Battery information indicates the remaining charge.

- Auto sleep and auto power off function to conserve battery life.

- USB1.1 communication port. Optional software to process the stored data on the PC.