Lizard LISS Software

The LISS™ software is the powerhouse that drives the Lizard® technology, whether for topside or subsea applications. The common interface ensures all users can readily apply the Lizard® technology to a variety of applications without the requirement for additional software training.

Description

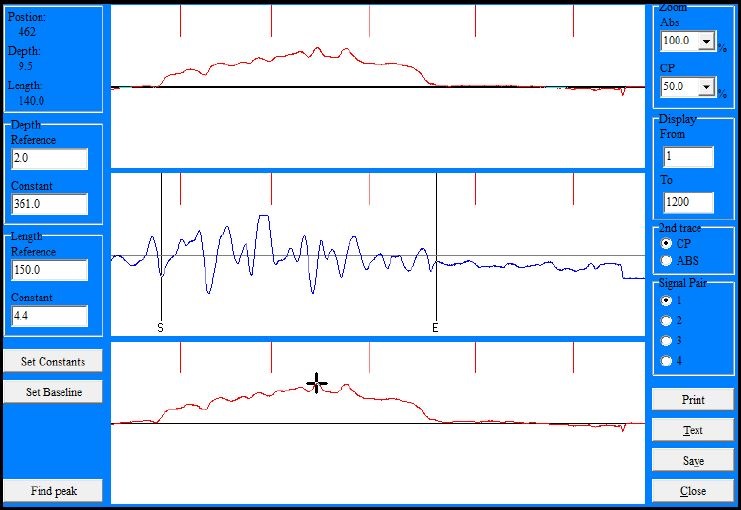

The LISS™ software is the powerhouse that drives the Lizard® technology, whether for topside or subsea applications. The common interface ensures all users can readily apply the Lizard® technology to a variety of applications without the requirement for additional software training. The Graphical User Interface (GUI) is deliberately designed to utilise graphical input by way of simple sliders for rapid data manipulation, with the option of hot keys for common tasks.

LISS™ provides an unparalleled level of data review from a single data set, switchable between various Plot modes to suit the application without the requirement to repeat scans. Most Plot modes within LISS™ typically feature data sets comprising of AC Field Measurement (Bx/Bz) and Classic Impedance information. This allows greater clarity of scan data and the ability to manipulate the Impedance output for even greater control of AC Field Measurement data.

The Lizard® technology and LISS software is an ideal fit for the inspection of railway vehicles and infrastructure due to the versatility of the Lizard® FGI system. The Lizard® FGI technology was identified by a major passenger vehicle manufacturer as a possible means of inspection technique for the wheel tread on their new build passenger trains. The Lizard® FGI technology was adapted to suit the profile of the wheel tread and configured to identify profile wear, crack location and severity as well as areas of work hardening (upper bainite and martensite) that were later identified to be areas of damage caused by a faulty set up of the ABS braking system. The manufacturer was able to feed the data obtained by the Lizard® technology back into the ride design team to address the issue ans significantly reduce wheel wear allowing longer periods between wheel re-profiling and replacement.

LISS™ operates within the Windows™ environment and as such features cross compatibility with other Windows software packages making report scripting quick and easy.