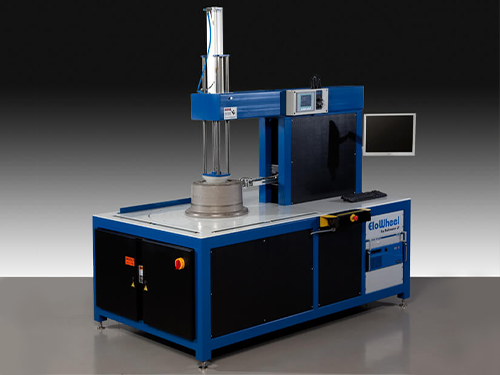

Rohmann EloWheel Aircraft Wheel Rim Test System

Description

The EloWheel System developed by Rohmann, Germany, is based on their long development history and expertise in the field of eddy current testing of aircraft wheel rims. This system offers fast, reliable, high sensitivity testing with the flexibility to adapt to future requirements. Utilising a turntable and pneumatically operated centering piston, the wheel halves are automatically scanned with probes on a lineal axis system. The standard probe is HF, testing for surface cracks. The optional LF probe is for subsurface testing for discontinuities extending to a depth of 25% of the wall thickness, starting from the inner surface of the wheel rim. For each wheel half, the test period can be between 25 seconds for a small rim, and up to 90 seconds for large main wheel rims.

Features include touchscreen capable software, providing several display modes such as waterfall display, C-scan, impedance plane etc.. The results of previous scans can be recalled and compared easily with the current scan.

The eddy current parameters are set with a reference standard that has 3-4 notches in the critical areas – notch positions and sizes are normally specified in the maintenance bulletin of the wheel manufacturer.

Flexible configuration of the equipment provides an easy integration path into most production and assembly lines.