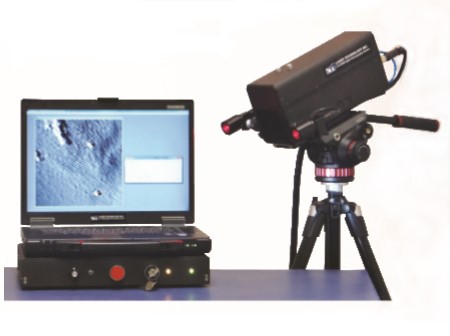

LTI-2100M COMPACT DIGITAL SHEAROGRAPHY CAMERA

Designed for fast and accurate non-destructive inspection of structures, components and repairs.

Description

The portable LTI-2100M features:

- Compact, rugged shearography camera: Lightweight and easy to use.

- Exceptional shearography image quality: 12-bit hi-definition sensor and diffraction limited optics.

- Powerful defect analysis tools: Easily programmable image processing macros in LaserNDT 1.8.0 Software Suite for improved operator image analysis and reporting.

- Versatile Camera: Easily mounts to scan gantries, robots, crawlers, tripods, vacuum attachments and customer defined test configurations.

- Test Configuration: All Mode Operation: Thermal, Vacuum, Vibration and Pressure Stressing.

- Options: Test Part Stressing Systems, Test Chambers, Gantries, Workstations, Robotic Scanners and Lasers to 2 Watts.

Materials:

- Carbon Fiber Laminate.

- Metal Honeycomb.

- Foam Cores.

- Composites.

- Metal-Metal Bonds.

- COPV.

Industries:

- Aerospace.

- Wind Power.

- Marine.

- Rail.

- Automotive.

Defect, Measure and Locate:

- Delaminations.

- Disbonds.

- Impact damage.

- Repair defects.

- Porosity.

- Cracks.

- Fiber waves or wrinkles.

System includes: Shear camera with a built-in 100 mw laser light source (Class IIIa), image processing computer, inter connect cables, tripod, transit case and Operator and Applications Manual.

Optional equipment: Thermal Stress Systems TES-50 (500W) or TES-200 (2kW) with software control and adjustable radiant beam spread.

Laser Shearography Certifications: AIA NAS 410, ASNT SNT-TC-1A, ASTM E2581-07 EN4179.