Rohmann Weld Inspection Kit

The Weld Inspection-Kit contains probes and accessories for the Non Destructive Testing of machined and un-machined welded joints.

Description

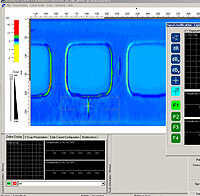

The Rohmann Weld Inspection-Kit was developed for identifying and evaluating cracks in weld seams. Whether testing is carried out on machined or un-machined weld seams, through lacquer coatings or on corroded surfaces, on ferritic or non-ferritic materials – wherever quick reproducible and cost-effective tests need to be carried out, the Weld Inspection-Kit is the correct choice.

Eddy Current Testing can be regarded as an alternative in these areas and also as a partial substitute for magnetic particle testing or dye penetrant testing.

In many cases, testing is also impeded by lacquer coatings of different thicknesses.

A key part of the testing task is the evaluation of the coating thickness followed by the optimization of the weld seam test. An absolute probe LAB-10 H-33 is included in the set for this purpose. The probe is also designed in a bridge circuit. LAB-10 H-33 and the crack detection probes BAL 73-1 and BAL-1 H-161 can be operated using the cable EKB-2-024.

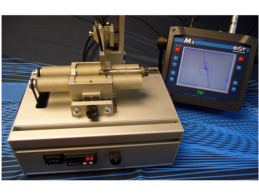

Both the ELOTEST M2 and the ELOTEST M3 are suitable test instruments for this purpose. Together with the Weld Inspection-Kit, the weld specimen TP 168 and the crack plate TP 11.02.1 with calibration foils made of plastic, lacquer coating thicknesses of up to 2 mm can thus be simulated and calibrated for testing.

Tests carried out with the Weld Inspection-Kit meet DIN EN 1711 Specifications.

For further information please email: ndt@ndt.com.au